- Riveting

- Thread creation

- Thread reinforcement

- Adhesive technology

- Decoupling

- Quick-release systems

- Build-to-print parts

- Standard parts

Industry solutions

The aerospace industry meets 360° joining technology

Fascination. Infinity. Innovation.

New technologies, reducing emissions, design concepts: Get on the early plane with us and give your developments the necessary drive.

Böllhoff – your expert for the aerospace industry

“Remove before flight” – who doesn’t want to fly safely? We also take a second look and support you when it comes to fulfilling the requirements of the current development trends of the aerospace industry. To increase the energy efficiency and save resources, aeronautical engineers and engine manufacturers also systematically analyse and optimise the production processes. For decades, we have been a partner for the industry and offer special joining solutions for every type – airplanes, helicopters, satellites, or space shuttles.

Get on the early plane with us and give your developments the necessary drive.

We are right where you need us — by your side.

We are happy to help

Do you have any questions or a current project?

Let us know – we will get in touch with you

Contact usYour modules – our joining solutions

We also supply the assembly solutions for our fasteners. Please do not hesitate to contact us for information about our complete range of processing systems for example: hand-held tools, robot-coupled hand-held tools or fully automatic solutions.

-

Cabin interior

-

Engine

-

Systems / Equipment

-

Airframe / Aero structure

-

Maintenance, repair and overhaul (MRO)

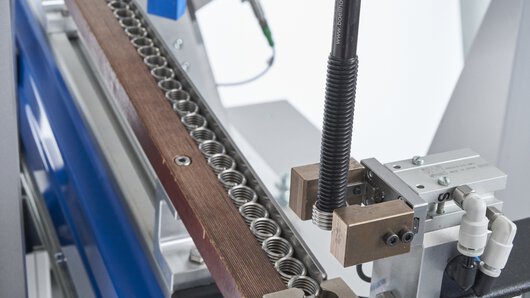

Automation

Automatic installation tools

We also supply the assembly solutions for our fastening elements, e.g. HELICOIL® or AMTEC® thread inserts, ONSERT® bonding solutions or RIVKLE® blind rivet nuts.

Our range includes modules for integration into automatic processes and complete systems.

Do you have specific requirements? If so, please contact us!

The Böllhoff competencies

Your partner for successful joining – and what that means for you.

-

Development and design competencies

-

Production

-

Qualification

-

Supply

Videos

Get inspired by our solutions

and take off with us.

Trade fairs, seminars and training courses

Our events

Visit us on different international aerospace exhibitions. You cannot join us at our booth? We would be pleased to offer tailored in-house events – on site in your facilities or digital.

Next Events